High-Quality Cold Rolled Steel for Critical Applications

COLD ROLLED STEEL STRIP AND SHEET PRODUCTS

COLD ROLLED STEEL

This product is made by cold-reducing descaled hot rolled coils to the desired thickness. Usually, the coils undergo further processing such as annealing and temper rolling to impart the desired formability, surface texture and flatness.

HOW IT WORKS

Cold reduction creates a thinner product, one with a thickness that cannot generally be obtained in hot rolled steel. In addition to being made thinner, cold reducing makes the steel harder and less ductile. The cold-reduced steel is then annealed (heated to high temperatures) to make it soft and formable.

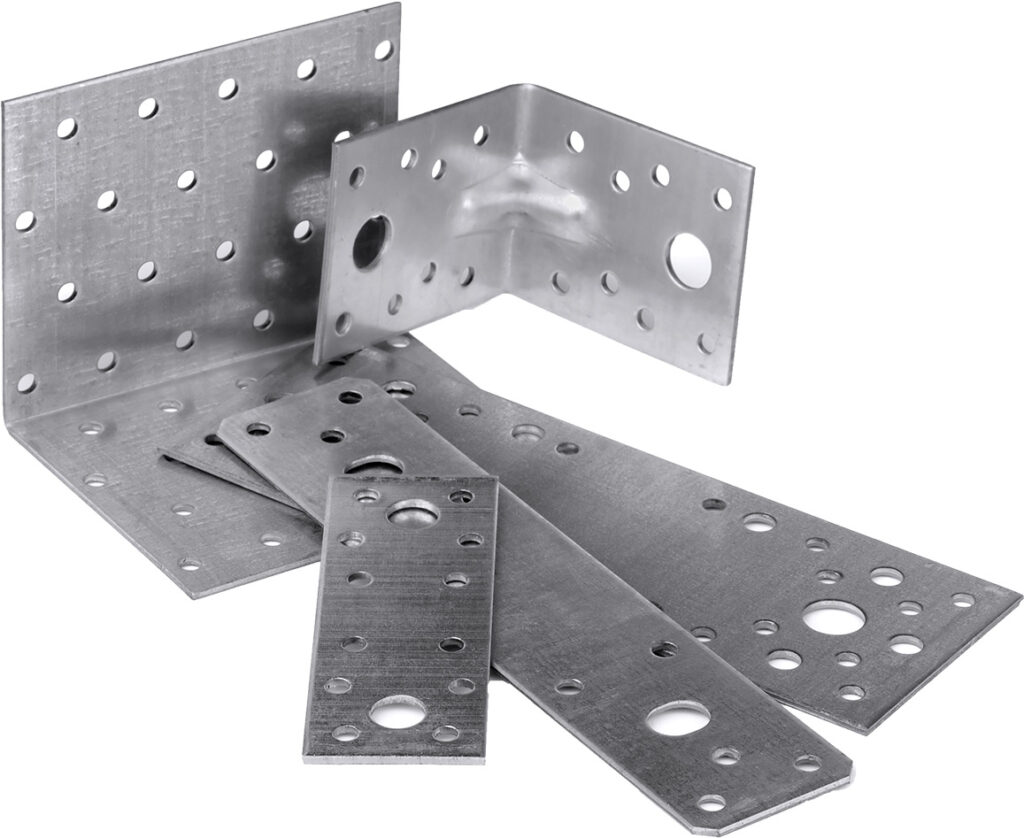

APPLICATIONS

Cold rolled steel is used in a wide variety of applications — from critical surface end uses such as automobile panels and appliance shells, to deep-drawn end uses such as heavy-duty filter shells, to high-strength end uses such as automotive door braces.

COLD ROLL (ASTM A1008)

Available in:

- Gauges ranging from .0142 to .187 (our limit)

- Tempers ranging from EDDS to full hard

WHY RANDALL METALS?

Randall Metals produces high-quality, cold rolled steel products for the automotive, consumer and commercial industries. With a range of metallurgical capabilities to meet your end-use needs, we can design cold rolled products to your desired characteristics, including formability, strength, deep drawability, dent resistance and printability.

Regardless of your industry or application, we are dedicated to the superior processing and distribution of cold rolled steel products. Let’s talk about your products — and our experience and capabilities. We look forward to working with you!